Spiral pipe equipment how to enhance stability?

来源:www.spiralweldedtubemill.com 发表时间:2018-02-08

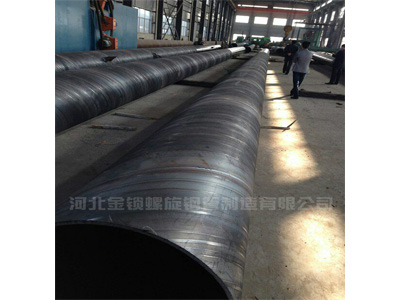

Due to the type of spiral pipe, the storage of this steel pipe is exquisite, so it can be related to the function of the spiral pipe. For some small medium-sized spiral pipes, they can be selected for storage in a ventilated shed, Under the mat to prevent the coil rust, some of the higher prices spiral metal products due to fear of corrosion, so it is best placed in the warehouse, so that the deposit can be as much as possible to maintain the spiral tube to add the stability of the spiral, Although it is able to put the spiral tube in the warehouse, but the selection of the warehouse is also required, the warehouse should pick a clean, clean and drafty local, away from some of the helical tubes harmful gases and dust. The ground requirement of the warehouse is that there is no weeds and debris, the reason for doing so is that you want to keep the net of this steel. Accumulation of spiral pipe warehouse should be stacked to prevent the accumulation of disorder, do not spiral pipe and corrosive items together. Spiral storage warehouse to be checked frequently, to prevent the rainy warehouse becomes wet, time to keep the storage conditions.

Spiral welded pipe equipment within the coating conditions

Cement mortar fabric construction, usually under the spiral pipe laying should be completed, pressure test and follow the planning pleading soil compaction. Fabric construction process, the pipeline is necessary in a stable situation. Assuming that the first pipe under the fabric after the anti-corrosion coating, it will be because the thin-walled steel pipe, the stiffness is small, in the construction of lifting, shipping, also occurred when the soil deformation and damage the coating.

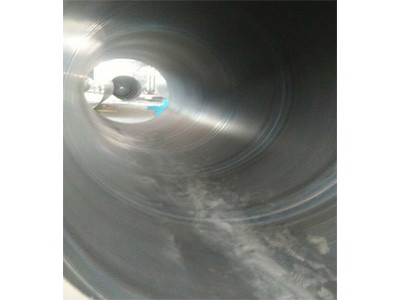

Fabric construction, the pipe wall is necessary to clean, remove the soft oxide scale, rust, soil, grease, welding slag and other attachments; the convexity of the inner wall of the pipe is not greater than the thickness of the anti-corrosion coating 1/3; Vertical deformation shall not exceed the planning rules, and not more than 2% of the pipe diameter.

Spiral welded pipe equipment, construction of anti-corrosion coating in order to ensure its stability!

Cement mortar coating optional mechanical spraying, artificial wiping pressure, dragons or centrifugal prefabricated construction. Assuming that it is necessary to use the prefabricated method to make the inner anticorrosive coating, protective measures should be taken for the anticorrosive coating during the transportation, installation and backfilling.

During construction, the mass blending ratio of cement mortar, cement and sand is 1: 1-2, the slump of cement mortar is 60-80 mm, and the compressive strength of cement mortar should not be less than 30 MPa.

Mechanical spray coating construction of cement mortar coating surface smooth, fine, uniform thickness, good effect. Foreign 1930s preliminary selection of mechanical spraying construction, China since the beginning of the 1960s has been in Shanghai, Qingdao, Dalian and other cities. Elected mechanical spraying method of construction, the elbow, tee, special pipe fittings and gate valve adjacent pipe sections can be used to modify the craft, and a smooth transition section and the mechanical spraying fabric phase.

Others, trailers or centrifugal prefabrication methods are also widely used, no longer specifically described here. No matter what method of construction and protection procedures are to ensure that the anti-corrosion layer of cement mortar cracks and hollow key links. Therefore, after the formation of the anticorrosive layer in the cement mortar, it is necessary to block the pipeline immediately and not to form air convection. After the final setting, the wet protection should be carried out. Generally, the protection time of Portland cement should not be less than 7 days. Slag Portland cement should not Less than 14 d; before the water should continue to plug, adhere to moist.