Longitudinal welding machine common fault

来源:www.spiralweldedtubemill.com 发表时间:2018-01-28

Longitudinal welding machine common fault

Longitudinal welding machine fault is relatively large, and the failure of the reasons are more complicated, often a result of a variety of reasons, or one can cause several results. Below we have a brief description of the more common fault straight seam pipe machine.

1 scratch

In the process of production of straight seam pipe machine tube blank scratches caused mainly by two parts, one guide mechanism, the second is the extrusion welding.

1. 1 guide scratches the body

Scratches of the guide parts generally occur on both sides of the tube blank. The adjustment of the guide structure with the guide sleeve is not reasonable and may cause scratches on the upper and lower surfaces of the tube blank. The main reason is that the height of the guide sleeve is not correct or the upper and lower guide roller bearings are damaged and the tube blank can not be well controlled so that the guide sleeve can be frictionally formed.

1. 2 Extruded welding organization scratched

Scratch caused by the squeegee, mainly occurred in the bottom of the tube, the reason is generally inconsistent hole type, the lower edge of the squeeze roller hole type and the height of the rolling line does not match, squeeze roller squeeze on the lack of force .

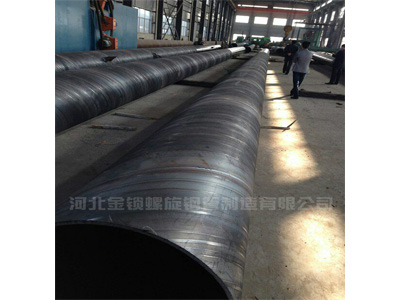

High-frequency straight seam welded pipe unit

2 weld quality problems

2. 1 long long welding

Lap welding refers to the two sides of the tube stack together after the formation of the dislocation bonding. In length, take the length of the welding points, long pass welding usually in the number of meters above, or even longer. There is a slight misalignment of a few tenths of a millimeter in misalignment, with complete misalignment equal to the wall thickness. The main reasons for the long pass welding due to the following factors: ① squeeze roller axial shift ② bearing damage ③ squeeze roller shaft bending ④ large squeeze pressure ⑤ tilt guide roller ⑥ guide the bottom of the roller diameter is different

2. 2 cycle lap welding

Longitudinal Welded Pipe Machine Lap Lap performance appears intermittent, sometimes without, and sometimes take a slightly longer welding length, a few centimeters and even tens of centimeters, and sometimes slightly shorter, one or two centimeters below. Sometimes take the welding for more regular equidistance appears, sometimes irregular appearance. Lap lap generally occurs in the middle and late stages of production, mainly due to the following reasons:

① guide ring rupture ② hole wear ③ hole-shaped arc foreign body ④ swing seam ⑤ bearing damage

2. 3 slit

Slit refers to the phenomenon of the weld is not bonded together, the slit length is generally more than a few centimeters or longer, the main reason for the following aspects:

① hole wear ② bearing damage ③ magnet ④ material