Standard and characteristics of spiral welded pipe

来源:www.spiralweldedtubemill.com 发表时间:2017-09-07

Yield Strength. Some of the metal material yield point is very obvious, there are difficulties in the measurement, so in order to measure the yield properties of the material, the rules of persistent residual plastic deformation is equal to the value of the stress, known as the yield strength or yield strength σ0. 2 .

Flexor ratio. The ratio of the yield point of steel to the tensile strength is called the yield ratio. The higher the strength ratio, the higher the reliability of structural parts, the general carbon steel yield ratio of 0.6-0.65, low alloy structural steel 0.65-0.75 alloy structural steel 0.84-0.86.

tensile strength. The maximum stress value of the material during the stretching process, from the initial to the time of cracking. It marked the steel to resist the size of the crack. And tensile strength corresponding to the compressive strength, bending strength and so on.

Elongation. After the material is broken, the length of the plastic elongation is the elongation or elongation as the percentage of the original sample length.

Hardness. Hardness indicates the ability of the material to withstand the hard objects pressed into its surface. It is one of the primary performance indicators of metal materials. The higher the hardness, the better the wear resistance. Commonly used hardness indicators are Brinell hardness, Rockwell hardness and Vickers hardness. Brinell hardness: with a certain load to the size of the hardened steel ball into the surface of the material, to maintain a period of time, after loading, the load and its indentation area ratio, that is, Brinell hardness value, the unit in kilograms force / mm2 The Rockwell hardness: When HB> 450 or the sample is too small, can not use Brinell hardness test and switch to Rockwell hardness measurement. It is a vertex angle of 120 ° diamond cone or diameter of 1.59,3.18mm ball, under a certain load into the surface of the measured material, the depth of the indentation from the hardness of the material. According to the hardness of the test material is not the same, divided into three different scales to indicate:

HRA: is the choice of 60kg load and diamond cone press the hardness obtained for high hardness of the material.

HRB: is the choice of 100kg load and 1.58mm diameter hardened steel ball, the hardness obtained for the lower hardness of the material.

HRC: is the choice of 150kg load and diamond cone press the hardness obtained for high hardness of the material.

Vickers hardness: the load of 120kg and 136 ° angle of the diamond square cone press into the material surface, with the material indentation pits divided by the surface area of the load value, that is, Vickers hardness

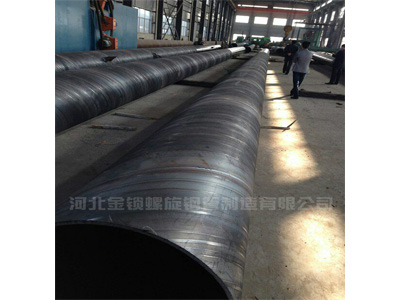

Spiral welded pipe equipment features: Longitudinal seam welded pipe production process Simple production efficiency High cost to carry out faster. The strength of the production equipment of the spiral pipe is generally higher than that of the straight seam welded pipe. The pipe with larger diameter is also produced with the same width of the blank. Spiral tube production equipment, but with the same length of the straight seam compared to the length of the weld to add 30 to 100% and the production rate is low. So the smaller diameter of the pipe are mostly used straight seam welding large diameter welded pipe is mostly used spiral pipe production equipment.

Spiral pipe production equipment and its specification Classification: Spiral seam submerged arc welded pipe for pressurized fluid transportation is mainly used for the transportation of oil and natural gas pipelines; high-frequency welding of high-frequency welding with spiral seam for pressurized fluid transportation High - frequency welded steel pipe for spiral seam for pressurized fluid transport. Steel pipe pressure capacity is easy to facilitate the welding and processing molding; general low-pressure fluid transport with spiral submerged arc welded steel pipe using double-sided active submerged arc welding or single-sided welding for water, gas, air and steam and other general low Commonly used norms of spiral steel pipe is now divided into: SY / T5037-2000 (part of the standard, also known as the general fluid transport pipeline with spiral seam submerged arc welded steel pipe), GB / T9711.1-1997 (GB API-5L (American Petroleum Institute, also known as pipeline steel pipe), SY / T5040-92 (pile with spiral seam submerged arc welded steel pipe), the same time,