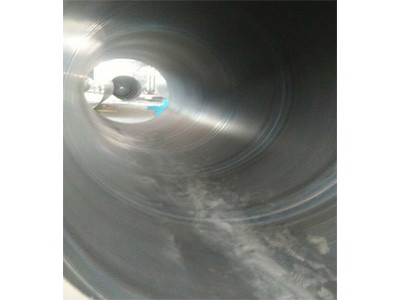

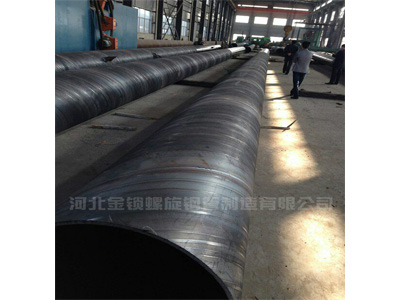

Spiral pipe rust and maintenance tips

来源:www.spiralweldedtubemill.com 发表时间:2017-12-09

Spiral welded pipe equipment, the phenomenon of rust is very common, then if there, how to deal with it?

Pickling rust. Two methods are generally used pickling treatment, respectively, chemical and electrolysis. Pipeline corrosion only need to use chemical pickling, you can remove the oxide layer, the old coating, rust, and sometimes can be used as reprocessing sandblasting rust. Although chemical cleaning can make the surface to a certain degree of cleanliness and roughness, but its anchor pattern shallow, and easy to cause environmental pollution. The company is located in:

Spraying (throwing) shot rust. This derusting method is driven by high-power motor spray (throwing) shoot blades at high speed rotation, so that steel balls, wire segments, grit, minerals and other abrasive centrifugal force under the action of spraying (throwing) on the surface of the pipe, not only Can completely remove rust, oxides and dirt, and steel in the abrasive under the impact of intense friction and friction, but also to achieve the required uniform roughness. The company is located in:

Spraying (throwing) shot rust, not only can expand the physical adsorption of the pipe surface, but also can enhance the coating and pipe surface mechanical adhesion. Therefore, spray (throwing) throw rust is ideal anti-corrosion pipe rust way. In general, shot peening (sand) rust is mainly used for pipe surface treatment, shot blasting (sand) rust is mainly used for pipe surface treatment. The company is located in:

Spray (throwing) shot rust should pay attention to several issues:

Rust grade steel used for the construction of epoxy-based process, ethylene, and phenol-based anti-corrosion coatings, generally require nearly white steel surface level (Sa2.5). Practice has proved that the use of this level of rust can almost get rid of all the scale, rust and other dirt, anchor depth of 40 ~ 100μm, fully meet the coating and steel pipe adhesion requirements, and spray The rust process achieves near whiteness (Sa2.5) with lower operating costs and consistent quality. The company is located in:

Spray (throwing) abrasive. The company is located in:

Abrasive materials should be selected based on the hardness of the pipe surface, the degree of original corrosion, the required surface roughness, the type of coating, etc. For single layer epoxy, two-layer or three-layer polyethylene coatings, a mixed abrasive of grit and steel shot Easier to achieve the ideal effect of rust removal. Shot steel has the role of strengthening the surface of the steel, while the grit has the role of etching the surface of the steel. Grit blasting and shot blasting (usually shots with 40-50 HRC shots and grit hardness of 50-60 HRC for various steel surfaces, even on grade C and D corroded steel surfaces , Rust effect is also very good.

Then the spiral pipe unit how to maintain and maintain it?

Lubrication is an important part of maintenance equipment, the unit according to the different parts of the different requirements, the use of thin oil and dry oil lubrication method.

Uncoiler, pinch delivery levelers, delivery machines, reducer lubrication with oil, artificial oil into the gearbox. Using HJ-28 rolling mill oil or SY1127-77S200 industrial gear oil. Check the oil once a month, a half a year oil change. In addition to oil cup plus dry oil, the remaining part of the adjustment will be a refueling time (HJ-50S mechanical oil). Gearbox maintenance is mainly the maintenance of the worm body, fueling parts shall not exceed the 2/3 position oil. Unit operation, we should always check the temperature of the shaft seat, generally not more than 40 ℃, the transmission parts of the relevant parts and components should always be checked and dealt with in time. Always replace the seal: the operator must change equipment before the shift, remove sand and scale, etc., should keep the equipment clean and make the shift record. Inspection cycle can be considered the following considerations: minor repairs quarterly, the first year in the repair time, two years overhaul. According to the actual usage, frequency, load and other users can be flexible and grasp.

For more information on Spiral Welded Pipe equipment please stay tuned to us. The company is located in:

Spiral welded pipe equipment, the phenomenon of rust is very common, then if there, how to deal with it?

Pickling rust. Two methods are generally used pickling treatment, respectively, chemical and electrolysis. Pipeline corrosion only need to use chemical pickling, you can remove the oxide layer, the old coating, rust, and sometimes can be used as reprocessing sandblasting rust. Although chemical cleaning can make the surface to a certain degree of cleanliness and roughness, but its anchor pattern shallow, and easy to cause environmental pollution. The company is located in:

Spraying (throwing) shot rust. This derusting method is driven by high-power motor spray (throwing) shoot blades at high speed rotation, so that steel balls, wire segments, grit, minerals and other abrasive centrifugal force under the action of spraying (throwing) on the surface of the pipe, not only Can completely remove rust, oxides and dirt, and steel in the abrasive under the impact of intense friction and friction, but also to achieve the required uniform roughness. The company is located in:

Spraying (throwing) shot rust, not only can expand the physical adsorption of the pipe surface, but also can enhance the coating and pipe surface mechanical adhesion. Therefore, spray (throwing) throw rust is ideal anti-corrosion pipe rust way. In general, shot peening (sand) rust is mainly used for pipe surface treatment, shot blasting (sand) rust is mainly used for pipe surface treatment. The company is located in:

Spray (throwing) shot rust should pay attention to several issues:

Rust grade steel used for the construction of epoxy-based process, ethylene, and phenol-based anti-corrosion coatings, generally require nearly white steel surface level (Sa2.5). Practice has proved that the use of this level of rust can almost get rid of all the scale, rust and other dirt, anchor depth of 40 ~ 100μm, fully meet the coating and steel pipe adhesion requirements, and spray The rust process achieves near whiteness (Sa2.5) with lower operating costs and consistent quality. The company is located in:

Spray (throwing) abrasive. The company is located in:

Abrasive materials should be selected based on the hardness of the pipe surface, the degree of original corrosion, the required surface roughness, the type of coating, etc. For single layer epoxy, two-layer or three-layer polyethylene coatings, a mixed abrasive of grit and steel shot Easier to achieve the ideal effect of rust removal. Shot steel has the role of strengthening the surface of the steel, while the grit has the role of etching the surface of the steel. Grit blasting and shot blasting (usually shots with 40-50 HRC shots and grit hardness of 50-60 HRC for various steel surfaces, even on grade C and D corroded steel surfaces , Rust effect is also very good.

Then the spiral pipe unit how to maintain and maintain it?

Lubrication is an important part of maintenance equipment, the unit according to the different parts of the different requirements, the use of thin oil and dry oil lubrication method.

Uncoiler, pinch delivery levelers, delivery machines, reducer lubrication with oil, artificial oil into the gearbox. Using HJ-28 rolling mill oil or SY1127-77S200 industrial gear oil. Check the oil once a month, a half a year oil change. In addition to oil cup plus dry oil, the remaining part of the adjustment will be a refueling time (HJ-50S mechanical oil). Gearbox maintenance is mainly the maintenance of the worm body, fueling parts shall not exceed the 2/3 position oil. Unit operation, we should always check the temperature of the shaft seat, generally not more than 40 ℃, the transmission parts of the relevant parts and components should always be checked and dealt with in time. Always replace the seal: the operator must change equipment before the shift, remove sand and scale, etc., should keep the equipment clean and make the shift record. Inspection cycle can be considered the following considerations: minor repairs quarterly, the first year in the repair time, two years overhaul. According to the actual usage, frequency, load and other users can be flexible and grasp.

For more information on Spiral Welded Pipe equipment please stay tuned to us.