Spiral pipe equipment Spiral view assembly

来源:www.spiralweldedtubemill.com 发表时间:2017-11-23

The primary components of a Spiral Pipe Equipment Straightener consist of the structural components, the underside of the structural assembly, the roller assembly, the roller assembly, the gear reduction assembly and the interrelationships of the various components.

Spiral pipe equipment in the straightener or billet straightening below the growth along the columnar crystal known as the foam hole. Close to the outer surface of the straightening machine slab, the relatively densely packed, relatively small bubbles are called holes. According to the helical pipe equipment leveler air bubble orientation, exposed appearance, known as the appearance of the bubble.

Shed foam is the primary cause of problems with spiral steel pipe equipment, but the high level of gas contained in the straightening equipment is an important factor in the formation of foam. With straightening machine casting process of air, water will attack bubbles. Shanxi spiral pipe equipment leveler appearance of the formation of bubbles, the general is the condensation process of steel elements, such as oxygen, hydrogen, nitrogen and carbon concentration of the condensation interface. When it constitutes CO, H2 and N2 gas, such as the total pressure is greater than the sum of static pressure and atmospheric pressure steel, there will be a foam composition. If these bubbles can not escape quickly from the steel, there will be bubble defects in the surface or subcutaneous of straightening machine straightening machine in Shanxi. Lack of continuous casting deoxidation will often attack straightening machine slab appearance or subcutaneous bubbles. Other operations also have a certain impact on the shortcomings of the bubble, such as exercise, the end of the control is not appropriate, molten steel, hydrogen peroxide or tapping a long time, high pouring temperature in the ladle refractories baking, will add steel dissolved Gas and lead to a series of bubbles.

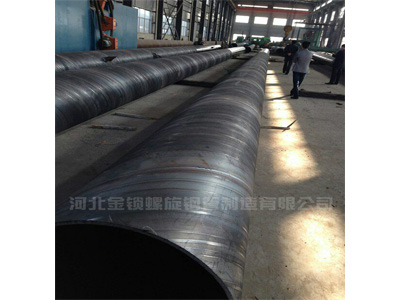

Spiral welded pipe equipment is low carbon carbon structural steel or low alloy structural steel strip according to the perspective of a certain spiral roll into the tube, and then the pipe seam welded together, it can use a narrower strip to produce large diameter Of the pipe, the spiral pipe is mainly used for oil and gas pipeline delivery, the standard diameter wall thickness shows that spiral welded pipe equipment with one-sided welding and double-sided welding, the pipe should ensure that the hydraulic test, the tensile tensile weld Strength and cold bending performance to comply with the provisions.

And when the spiral pipe equipment explodes, because the weld is subjected to the normal stress and the component stress is relatively small, the explosion port generally does not originate from the spiral pipe equipment, its safety is higher than the straight seam welded pipe, because the radial stress is present in The maximum stress on the pipe, so the weld is in the direction of straight stress to accept the maximum load. The straight seam to accept the maximum load. Hoop weld to accept the smallest load, spiral seam between the two. Spiral pipe equipment, the helix angle of the weld is generally 50-75 degrees, so the composition of the spiral weld stress is straight seam welded pipe 60-85% of the main stress.

In the same working pressure, the same diameter spiral welded pipe than the straight seam welded pipe wall thickness can be reduced. Spiral pipe equipment according to the cross-sectional shape of the different can be divided into round tube and special-shaped tube. Because the circumference of the flat conditions, the largest circular area, with a circular tube to carry more fluid. In addition, the circular cross-section of the internal or external radial pressure to accept more uniform force, therefore, the vast majority of pipe is a round tube. After comparing the experimental results, it is verified that the yield pressure of the spiral welded pipe equipment and the longitudinal welded pipe is in good agreement with the actual value of the explosion pressure and the theoretical value, and the deviation is near. However, the yield stress is still the explosion pressure, spiral welded pipe are lower than the longitudinal welded pipe.The explosion experiment also shows that the helical welded pipe explosion mouth ring deformation rate was significantly greater than the longitudinal welded pipe.Thus proves that the spiral pipe plastic deformation capacity Better than the straight seam welded pipe, the explosion is generally limited to a pitch of only one pitch, which is spiral welded pipe equipment on the expansion of the seam played a strong binding effect caused. When the spiral welded pipe equipment adjacent to the existence of shortcomings parallel to the shortcomings, because the spiral welded joints less stress, so the risk of expansion is not as large as the straight weld. Spiral welded pipe equipment is used as a conduit for transporting fluids such as pipes that carry oil, gas, gas, water, and some solid materials. Steel and bar steel and other solid steel, torsional strength in the bending phase together, the lighter components, is an economical section of steel.