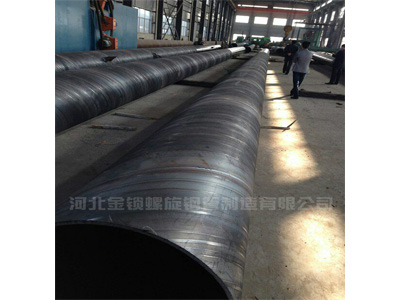

Spiral welded pipe to adjust knowledge

来源:www.spiralweldedtubemill.com 发表时间:2017-11-10

First, rolling the bottom line

Rolling the bottom line is the center line of the unit and the flat roll throat diameter (the thinnest) with the straight line, the distance between the line and the table, that is, the diameter of the roll throat and floor distance. The bottom line of the rolling mill has been set at the time of delivery. For example, the bottom rolling height of 50 units is 235mm, the bottom rolling line of unit 76 is 265mm, and the bottom rolling line of unit 89 is 280mm. Different manufacturers, this data will change. Vertical roller under the roll ring from the bottom of the bottom plate is also the bottom line of the rolling height (vertical roller shaft height adjustable unit).

Second, the initial bottom diameter and bottom diameter increase

The start of each unit (forming the first one is W variant, bottom diameter in the middle of the most thick and thin) bottom diameter (flat roll throat) is also fixed, increasing 0.6MM-0.8MM per order, increasing The purpose is to make each order slightly faster than the previous one, belonging to the front pulled in front of the pipe forming favorable.

Third, the height of the insurance pad

The safety pad is a cast iron cushion placed between the lower slider and the archway bottom beam. When the pad is relatively large, the pad will be pressed into the bottom to prevent the shaft from being damaged. The height of the insurance pad is also fixed, decreasing 0.3MM-0.4MM per each order (due to the roller increasing 0.6MM-0.8MM per order, the insurance pad decreasing 0.3MM-0.4MM per order, so the rolling bottom line is still at the level).

Fourth, the round change when the fixed-diameter rolling bottom line changes

In the round change side, especially when the round tube (flat out), the diameter should be adjusted to the center line unchanged, the bottom line is gradually increased. The purpose of this adjustment is to make pipe uniform deformation, equal angle, reduce the impact on the unit. Example: 50 * 100 rectangular tube (sizing for the five flat five legislature, four sorts of flat roller pass the same type), the squeeze roll out of a diameter of 94 circles to sizing the fourth time when the amount of deformation 94-50 = 44MM (the same as the bottom line is not equal to the upper tube pressure 44MM, the thick wall thick impact on the unit is very large, and the lower part of the outer R angle than the upper outer R angle), so should use the center line Unchanged, that is, the next flat roller gradually raised (rolling bottom line gradually increased), to sizing the fourth time when the cushion pad 22MM, 22MM four evenly divided pad can be (this is the probability algorithm, the exact pad Data should be a variation of roll design).